Our shutter valves are suitable in applications with large products, high viscous or strict requirements minimizing pressure loss. The shutter valve range is designed for use in the food, chemical, pharmaceutical and other industries with high hygiene requirements.

Application

MH Koltek valve is a manually or pneumatically operated valve, designed for use in the food, chemical, pharmaceutical and other industries where valves of sanitary design are needed.

Product Benefits

- Sanitary design

- Standard Design

- Use in the food, chemical, pharmaceutical

Standard Design

The valve consist of a rigid body with an internal cylindrical bore and 2 or 3 ports for pipe connection. The two lids have guide rings for an internal shaft which supports and positions the shutter.

The stainless steel handle or the actuator is fitted to turn the shaft.

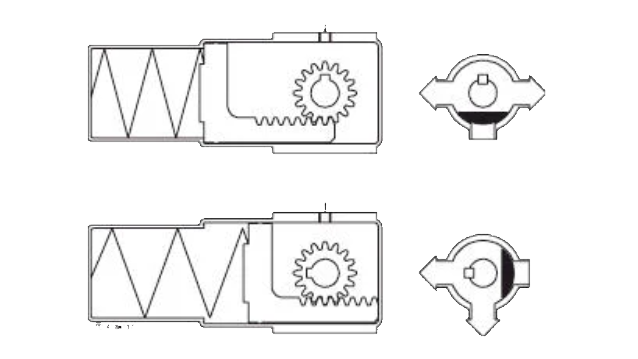

The actuator consists a system of cylinders and one or two main pistons interconnected with a toothed bar which interacts with a gear wheel on the valve shaft. The system is insensitive to pressure shocks in the valve.

The valve has welding ends as standard.

How it works

Working principle

A PTFE shutter is operated by means of a handle or an actuator. A spring system presses the shutter against the inside cylindrical surface of the valve body thus ensuring complete tightness.

The air actuated valve can be fitted with ThinkTop® or a laterally fitted indication unit for remote indication of the valve position. The manually operated valve can be fitted with laterally indication units (used for LKLA actuators). The actuator for the valve comes in two versions, single acting or double acting. The single acting actuator operates with one main piston whereas the double acting actuator operates with two main pistons.