The special features of SolidC UltraPure centrifugal pumps include an external shaft seal ad spring, a defined-compression O-ring on the back plate, crevice-free design and special standards-compliant materials throughout.

Discover Alfa Laval SolidC UltraPure

Alfa Laval SolidC UltraPure pumps strike the perfect balance between price and performance.

Value

The SolidC UltraPure is a standardized centrifugal pump design that is a perfect choice for installations where price and performance are central.

Repeatability

An external shaft seal, a semi-open impeller with balance holes, and a crevice-free design ensure repeatability and a high-quality end product.

Reliability

Alfa Laval provides a 3-year warranty on all non-wearing parts on the SolidC UltraPure and all standard componets are kept in stock to help you avoid unnecessary downtime.

Global coverage with local presence

SolidC UltraPure units are available in four different sizes. All standard components are kept in stock to shorten lead times and to avoid any unnecessary downtime.

Experts are close at hand, no matter where you are, we have support and service experts close by. At the same time, all UltraPure pumps use standardized parts for easy specification and delivery, and fast service turnaround.

Certification, specification and standards

The SolidC UltraPure range has EHEDG certification. Read more about SolidC UltraPure in product documentation.

How it works

SolidC UltraPure construction

The pump consist of a standard motor, stub shaft, mechanical compression coupling, stainless steel adaptor, back plate, impeller, pump casing and shaft seal.

Unique impeller design

SolidC UltraPure centrifugal pumps feature a unique semi-open impeller with a special vane design that ensures particularly low NPSHr (Net Positive Suction Head required), which is the total pressure at the suction nozzle necessary for the pump to operate properly. This helps prevent cavitation effects, and minimizes any risk of mechanical damage.

The impeller also features balancing holes that provide excellent circulation in the shaft seal area as well as reducing axial forces on the impeller. This reduces wear on both the shaft seal and the bearings of the drive motor.

Semi-open impeller with balancing holes for high cleanability of the shaft seal.

External shaft seal

The front-loaded external shaft seal, with the spring and washers mounted on the atmospheric side, is an important feature of the SolidC UltraPure design. This configuration makes maintenance rapid, easy and inexpensive – it only takes about 5 minutes to replace the shaft seal.

Using a front-loaded shaft seal, combined with the pipe couplings mounted on the pump housing, also means there is no need to disconnect or remove the pump casing for inspection or maintenance. This saves time and money, and helps keep downtime to a bare minimum. This feature also means that a spare pump without casing could also be quickly put into place.

Alfa Laval uses the same shaft seal for the whole SolidC UltraPure range – and the same seal is used in LKH UltraPure centrifugal pumps. This standardization keeps inventory down and makes replacing wearing parts a quick and easy task.

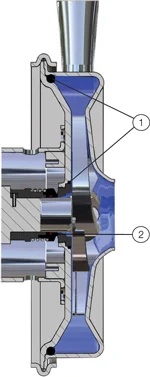

1: Defined O-ring groove providing firm positioning of the O-ring on pump casing and metal to metal contact provides a predefined compression of the O-rings with no crevices for contaminants.

2: External shaft seal with few wear parts and spring mounted on the atmospheric side, meaning no wear of the spring or other internal parts going into your product.