Alfa LKH UltraPure pharmaceutical pumps (certified to EHEDG) use a combination of optimised inlets and advanced impeller design to give unobstructed product flow, very low NPSH requirements and excellent hydraulic efficiency to keep your process running smoothly. They are designed for CIP and available in capacities of up to 500 m3/h and pressures of up to 190 m (19 bar).

High efficiency and economical centrifugal pump that meets the requirements of hygienic processes

- Low contamination risk – hygienic design with pharma-grade SiC+ seals, pre-defined compression elastomers and low-delta ferrite impeller

- Maximized uptime and reduced maintenance costs – robust mechanical design and ease of maintenance with modular front-loading seals

- Increased yield – comes with full material traceability and USP Class VI elastomers to reduce risk of process contamination from extractables

- Energy and cleaning efficient – precise hydraulic design energy costs and CO2/waste chemical emissions to boost yields and process sustainability

- Smooth qualification, validation and process control – material traceability, and pump supplied with Alfa Laval’s Q-Doc package in line with GDP

The vane design of the semi-open impeller ensures a low Net Positive Suction Head required and prevents the effects of cavitation. The impeller balance holes help circulate the process fluid in the shaft seal area reducing axial force and wear on the seal and motor bearings. The high flow around the pump, especially behind the impeller near the shaft seal, makes cleaning easy and enhances the lubrication/ cooling of the seal to prolong life.

Discover Alfa Laval LKH UltraPure

A further addition to the market leading Alfa Laval LKH pump platform, Alfa Laval LKH Prime UltraPure is characterized by superior performance, high quality and reliability for improved operational productivity. The Alfa Laval LKH UltraPure, part of the UltraPure portfolio, delivers maximum uptime and high efficiency for pharmaceutical applications.

Sizes and options

The LKH UltraPure comes in eight different standard sizes with capacities of up to 275m3/hour. A smart choice for pump duties that require continuous operation, the LKH UltraPure centrifugal pump delivers the highest possible efficiency and minimizes energy consumption. It is also available with a wide range of options for:

- Shaft seals

- Flushing arrangements

- Elastomers

- Surface finishes

- Drain options

- Passivation

- Hydrostatic testing

Total peace of mind with complete documentation for validation

All equipment and components in the Alfa Laval UltraPure portfolio are supplied with Alfa Laval Q-doc, a comprehensive documentation package that provides full transparency of the entire supply chain, from raw material to final equipment delivery. This smoothes purchasing and installation procedures as well as facilitates qualification, validation and change control procedures. Based on GDP (Good Documentation Practice), Alfa Laval Q-doc covers every aspect of UltraPure equipment supply and provides customers with transparent and well-documented quality assurance of the sourced equipment.

The Q-doc package for comprises performance tests, material certificates, traceability of product wetted parts and the necessary parts and service information.This attention to detail maximizes uptime and minimizes risk.

How it works

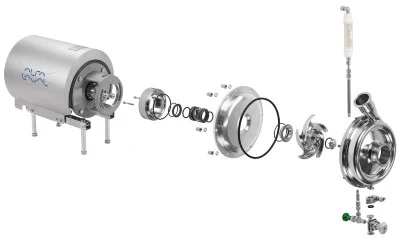

The LKH UltraPure centrifugal pump consists of a motor, impeller, pump casing, back plate, mechanical seal, legs, pump shaft/connections and adaptor. We use the same shaft seal for all UltraPure centrifugal pumps, regardless of size or model. This standardization reduces inventory and makes wear parts replacement quick and easy.

Inside the pump casing, the semi-open impeller rotates along with the pump shaft. The rotation of the impeller blades conveys energy to the fluid causing it to move in a circular direction. The movement of the fluid increases in velocity which is partly converted into pressure before it leaves the pump through the outlet.

All LKH UltraPure pump shaft seals are machined to stringent requirements and meet the flatness requirement of 3 light bands* or less. The stationary seal ring is fixed to the back plate providing perfectly aligned seal surfaces even after long periods of operation/vibration and can withstand potential pressure shocks.

The balanced design and use of spring force contribute to pressure equalization within the shaft seal area. This minimizes the risk of opening during unforeseen events, such as pressure shock.

The defined O-ring groove securely positions the O-ring on the pump casing and ensures metal to metal contact and predefined compression of the O-rings with no crevices for contaminants.

The external shaft seal has few wear parts and is spring-mounted on the atmospheric side. This means no spring wear and reduces contamination risk.

*Measured at 20°C, one light band corresponds to 0.3 µm flatness over the entire sealing surface.