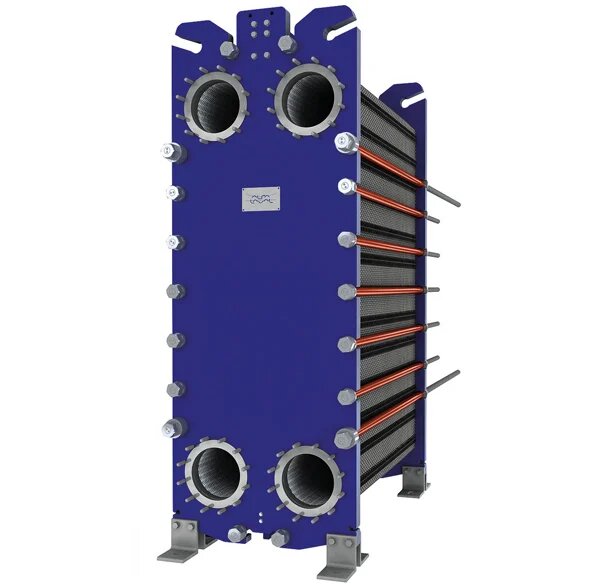

WideGap gasketed plate heat exchangers are designed for fibrous fluids and for fluids containing coarse particles. The wide gaps between plates allow fibers and particles to easily pass through the heat exchanger with minimum clogging.

They can be configured with wide-wide or wide-narrow channels, which make the units ideal for heating, cooling and interchanging duties. The smooth port design ensures fibers don’t get stuck at the entrance.

Applications:

- Sugar

- Bioethanol

- Pulp and paper

- Petrochemicals

- Condensers for heat recovery

Benefits

WideGap heat exchangers have much higher thermal efficiency and better flow geometry than a conventional alternative such as shell-and-tube heat exchangers, leading to benefits such as:

- Compact size - occupies as little as 20% of the floor space and is about 80% lighter when filled with process media

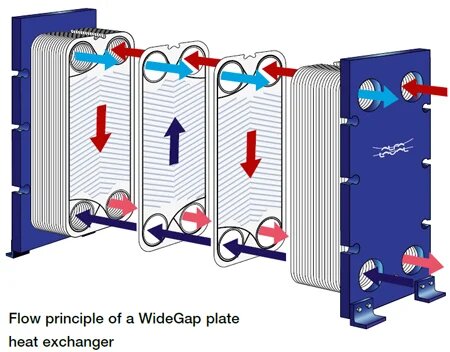

- Better heat recovery- thanks to the WideGap's counter-current flow, it can heat the cold stream to a temperature very close to that of the entering hot stream

- Increased production - service intervals are longer because clogging is minimized

- Flexible - easily optimize performance by reconfiguring the plates to fit the new operating conditions

How WideGap Works

The heat transfer area of a gasketed plate-and-frame heat exchanger consists of a series of corrugated plates, assembled between the frame and pressure plates, which retain the design pressure. The sealing between the plates is made of gaskets. For the highest thermal performance and to enable a very close temperature approach, fluids normally run counter-currently through the heat exchanger. The WideGap heat exchanger is tailor-made to handle fibrous fluids, highly viscous fluids, and fluids containing coarse particles. Because of the plate pattern and pressing depth design, these fluids flow easily through the heat exchanger.

High flow turbulence between plates results in higher heat transfer; however, the consequence is pressure drop. Our thermal design engineers can help you design and select the model and configuration that is suitable for your application needs while delivering maximum thermal performance and minimizing pressure drop.

Configurations

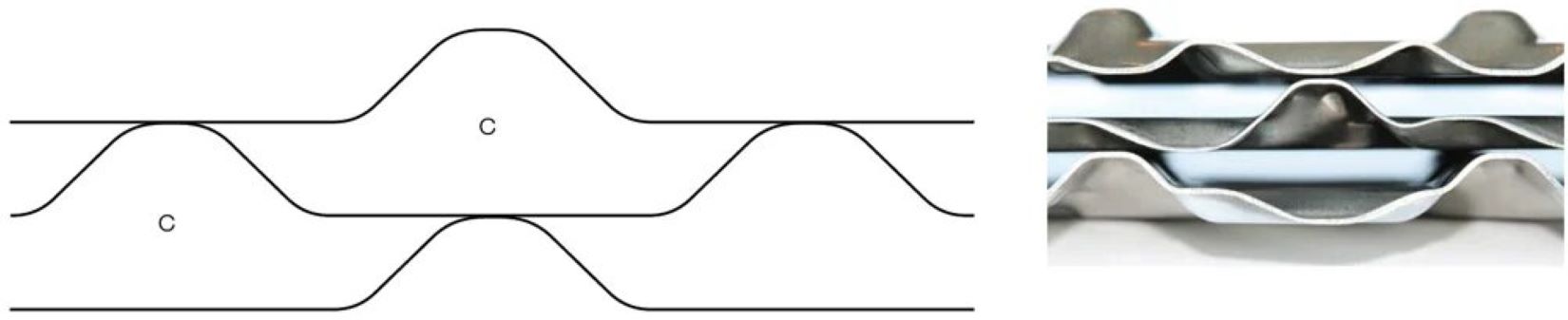

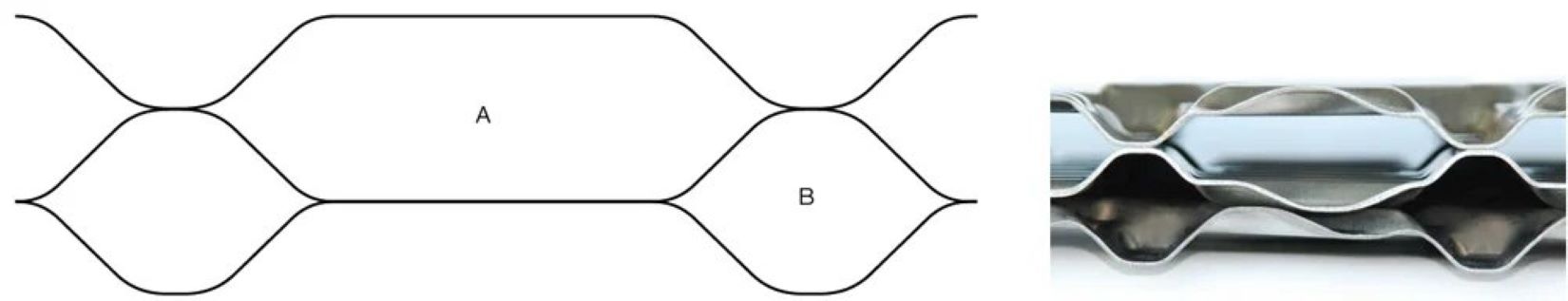

The WideGap heat exchanger can be configured in many ways. The channels can have either a wide/wide gap or a wide/narrow gap with different channel gaps. WideGap heat exchangers are usually configured as multi-pass in order to ensure enough turbulence. The pictures below show cross section views of the two different plate pack configurations.

Single sided WideGap

One extra wide channel for fibrous/dirty flued (A) and one channel for non-fibrous fluid (B).

Double sided WideGap

Two wide channels for fibrous/dirty fluids (C).