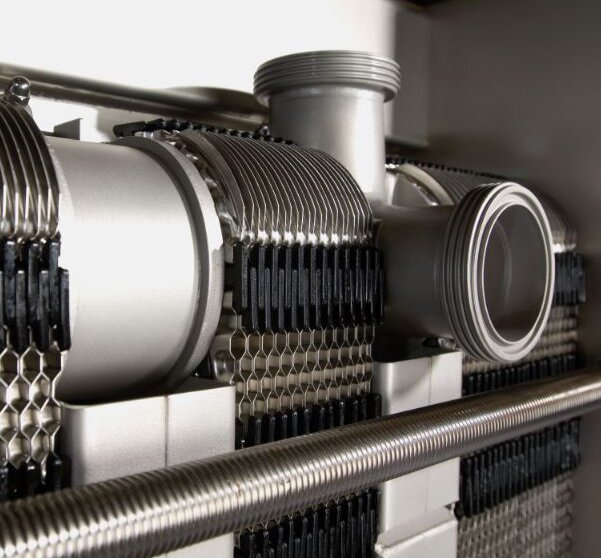

Alfa Laval FrontLine is our premium range of plate heat exchangers for applications with the strictest demands regarding hygienic control as well as gentle product treatment, long operating time and superior cleanability. Suitable for applications with specific hygienic needs such as beverages, dairy and food, FrontLine is the superior choice for heat sensitive media. The flexible design makes for easy rebuild.

Designed for gentle, uniform heat transfer for sensitive hygienic products

- Superior hygienic performance from plates developed specifically for food and other hygienic applications (FCM compliant)

- Gentle, uniform treatment and reliable performance ensured by wide choice of heat exchanger plate materials and plate patterns

- Flexible configuration and easy to maintain for long service life

- Specific fouling-resistant design provides for long running times

- Range of plates makes FrontLine easily scalable to ensure consistent product quality

Alfa Laval’s FrontLine range uses glue-free gaskets made from FDA-compliant materials that are easy to maintain and have a long service life. The frame can be used for multi-section applications (eg for pasteurization) and is easy to disassemble for inspection, cleaning, and service. Connection plate corners are interchangeable and heat transfer plates can easily be added or removed, so it is quick and easy to modify if process conditions change.

Plate types for different hygienic needs

FrontLine is available with three different types of plates, all of which are designed for sensitive, hygienic applications and uncompromising cleanliness.

- Clip plate – has a chevron plate pattern designed for hygienic conditions. The entry points, the distribution area, and the shape and depth of the pressed plate pattern allow for optimal performance.

- Clip plate Gemini double wall – consists of two plates pressed together. This prevents cross contamination between fluids in case of leakage through the plates.

- Clip plate WideStream – has a wider plate pattern with fewer contact points, which makes it ideal for products containing pulp or fibres.

FrontLine’s plate pattern and pressing depth are designed for gentle, uniform heat treatment of sensitive dairy, food and beverage products. Examples of applications include:

- Pasteurization of yoghurt, ice cream and beer

- Pasteurization of fruit juice with fibres

- Heating and cooling of viscous products

Alfa Laval BaseLine is recommended for less demanding hygienic applications.

How it works

Channels are formed between the plates and the corner ports are arranged so that the two media flow through alternate channels. The heat is transferred through the plate between the channels, where the counter-current flow helps attain the highest possible efficiency. The corrugation of the plates provides the passage between the plates, supports each plate against the adjacent one and enhances the turbulence, resulting in efficient heat transfer. Our thermal design engineers will help you design and select the model and configuration that is suitable for your application needs while delivering maximum thermal performance and minimizing pressure drop.

Alfa Laval hygienic liquid/liquid GPHE

Alfa Laval multi-section pasteurizer GPHE